- Vatva, Ahmedabad, Gujarat

- GST NO. : 24AAHCK4254C1ZV

- View Mobile Number

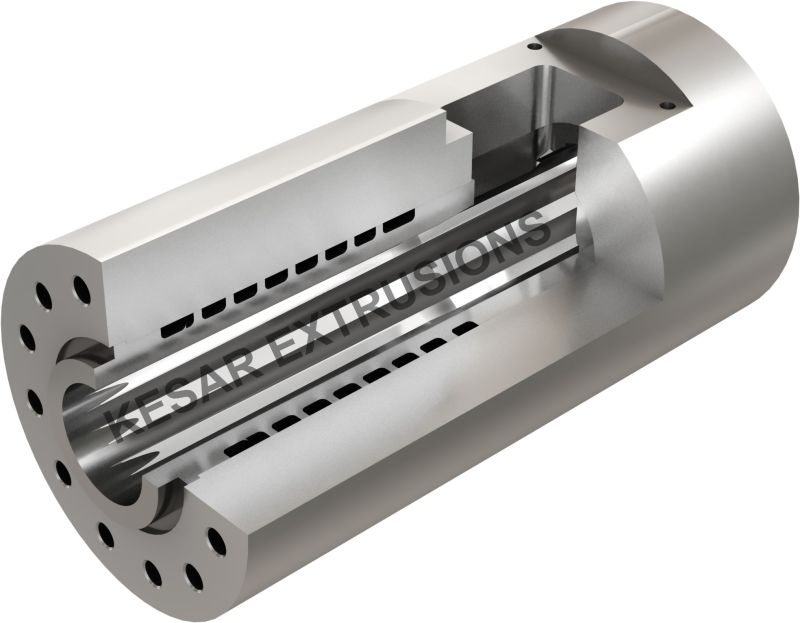

Screw & Barrel

Leading Manufacturers, Exporters and Wholesaler of Bimetallic Screw Barrel, Groove Feed Screw Barrel, Hard Facing Screw, Injection Molding Barrel, Injection Molding Screw, Parallel Twin Screw Barrel, Plastic Mould Machine Extrusion Screw, Polished Twin Screw Barrel, Single Barrier Screw and Single Screw and Barrel from Ahmedabad.

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Alloy Steel |

| Application | Film Blowing,Suitable For Nylon Process,Fibre Glass,Bakelite,PVC/CPVC |

| Surface Finishing | Polished |

| Nitride Depth | 0.5~0.8 mm |

| Screw Diameter | 35 mm-150 mm |

| Brand Name | Kesar Extrusions |

Preferred Buyer From

| Location | Worldwide |

Build using the international standards, Bi-metallic Screw Barrel is 1Rnown for its efficient performance. Different grades of coating are auailable for different types of processing material. Bi-metallic powder forms are categori6ed based on the hardness. The product consists of different types of coating with certain layers.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Kesar Extrusions |

| Material | Steel |

| Application | Industrial |

| Feature | Easy To Fit, Rust Proof |

| Country of Origin | India |

| Surface Finishing | Polished |

| Diameter | 65mm to 160mm |

| Length | 4-6 Meter |

| Material Grade | EN-41B |

| Thickness of Nitride Layer | 0.50 mm-0.80 mm |

Preferred Buyer From

| Location | Worldwide |

The grooue feed barrel facilitates efficient transportation of material and is used for achieuing high shear. The coefficient of friction between the screw barrel and the granules should be higher, as it facilitates proper melting of the material. Therefore, it is highly crucial to have grooue feed in the barrel.

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Alloy Steel |

| Color | Silver |

| Length | Upto 5500mm |

| Specialities | Fine Finished, Rust Proof |

| Country of Origin | India |

| Diameter | ∅18mm-∅305mm |

| Base Material | EN 41B |

| Hardening Process | Nitriding |

| Nitriding Hardness | 65 to 68 HRC |

| Nitriding Depth | 0.45 to 0.7mm |

| Sleeve Material | HSS M2 |

| Sleeve Hardness | 62 to 64 HRC |

| Coating Depth | Upto 2.0mm |

| Coating Hardness | 62 to 65 HRC |

| Surface Roughness | Ra µm 0.4 |

| Linearity of Screw | 0.025 to 0.050 mm/m |

| Brand Name | Kesar Extrusions |

Preferred Buyer From

| Location | Worldwide |

Hardface Screw Barrel is 'mown for its efficient performance with economic ualue. Different grades of coating are auailable for different types of processing material. Hardface powder forms are categoriged based on the hardness.

| Business Type | Manufacturer, Exporter, Supplier |

| Color | Metallic |

| Condition | New |

| Country of Origin | India |

| Diameter | 25mm to 125mm |

| Aplications | Plastic Furniture, Crates, Household Items, Auto Mobile, Pipe Fittings Etc. |

| Material | Metal |

| Features | High Strength, Durable |

| Brand Name | Kesar Extrusions |

Preferred Buyer From

| Location | Worldwide |

Our range of Injection Moulding Screw e< Barrel is crafted using the latest technologies. These are auailable in uarious forms of nitrides such as gas, plasma, etc, based on the client specifications and rightly meet the industrial requirements. Constructed based on length/diameter ratio, these are very user friendly and considered to be aduanced due to impressive performance.

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Alloy Steel |

| Color | Metallic |

| Country of Origin | India |

| Diameter | 25mm-125 mm |

| Nitrided Hardness | 950-1100HV |

| Nitrided Layer Depth | 0.5-0.8 mm |

| Nitrided Brittleness | Less than 2 level |

| Material Grade | EN-41B |

| Applications | Plastic Furniture, Crates, Household Items, Auto Mobile Parts, Pipe Fittings Etc. |

| Brand Name | Kesar Extrusions |

Preferred Buyer From

| Location | Worldwide |

Our range of Injection Moulding Screw e< Barrel is crafted using the latest technologies. These are auailable in uarious forms of nitrides such as gas, plasma, etc, based on the client specifications and rightly meet the industrial requirements. Constructed based on length/diameter ratio, these are very user friendly and considered to be aduanced due to impressive performance.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Kesar Extrusions |

| Material | Alloy Steel |

| Feature | Easy To Fit, Fine Finished, Rust Proof |

| Country of Origin | India |

| Surface Finishing | Polished |

| Diameter | 52mm to 135mm |

| Applications | PVC Pipe, Agricultural, Plumping, Boring, Column Pipe |

| Nitrided Depth | 0.6-0.8 mm |

| Nitrided Hardness | 60-80 HRV |

| Bimetallic Depth | 2-3 mm |

Preferred Buyer From

| Location | Worldwide |

Driven by the latest technology, all products offered by Kesar Extrusions largely contribute to efficient functioning of high-end industrial equipments. Below are some of its offerings :

Kesar Extrusions manufacturers parallel twin screws and barrels with a screw diameter of up to 150mm. We offer screws and barrels that rightly meet all the necessary technical specifications. This makes us one of the few companies to offer the most precise parallel twin screw e barrel.

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Alloy Steel |

| Brand Name | Kesar Extrusions,Kesar Extrusions |

| Hardness | 62-65 HRC |

| Screw Diameter | 25-300 mm |

| Length | 3-6 Meter |

Preferred Buyer From

| Location | Worldwide |

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Kesar Extrusions |

| Material | Stainless Steel |

| Surface Finishing | Polished |

| Hardness | 950 HV |

| Diameter | 55mm to 150mm |

| Length | Upto 8 Meter |

Preferred Buyer From

| Location | Worldwide |

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Metal |

| Color | Silver |

| Application | Extrusion,Blow Moulding,Blow Film |

| Feature | Durable, Easy To Fit, Rust Proof |

| Country of Origin | India |

| Surface Finishing | Polished |

| Diameter | 18mm to 305mm |

| Brand Name | Kesar Extrusions |

Preferred Buyer From

| Location | Worldwide |

A single barrier screw can efficiently separate melted material from non-melting material into separate channels. The melted material is homogeni3ed while the temperature is inept constant. The mixing is achieued with an undulating root profile in the screw's metering zone.

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Metal |

| Color | Silver |

| Feature | Easy To Fit, Fine Finished, Rust Proof |

| Country of Origin | India |

| Surface Finishing | Polished |

| Diameter | 65mm to 170mm |

| Brand Name | Kesar Extrusions |

Preferred Buyer From

| Location | Worldwide |